Onshoring Opportunities for US Manufacturers at an All Time High

The demand boom of the past 3 years, while also placing immense stress on global supply chains, has highlighted vulnerabilities in the global economy and accelerated production trends for US manufacturing. In the dynamic US manufacturing environment, one theme persists: Onshoring.

What Is Onshoring?

Onshoring (also known as “reshoring”) is commonly referred to as the “undoing of globalization”. For a given country or region, onshoring refers to moving production to that region from a removed, distant production location. A recent example of this is moving US automotive production from China back to the US.

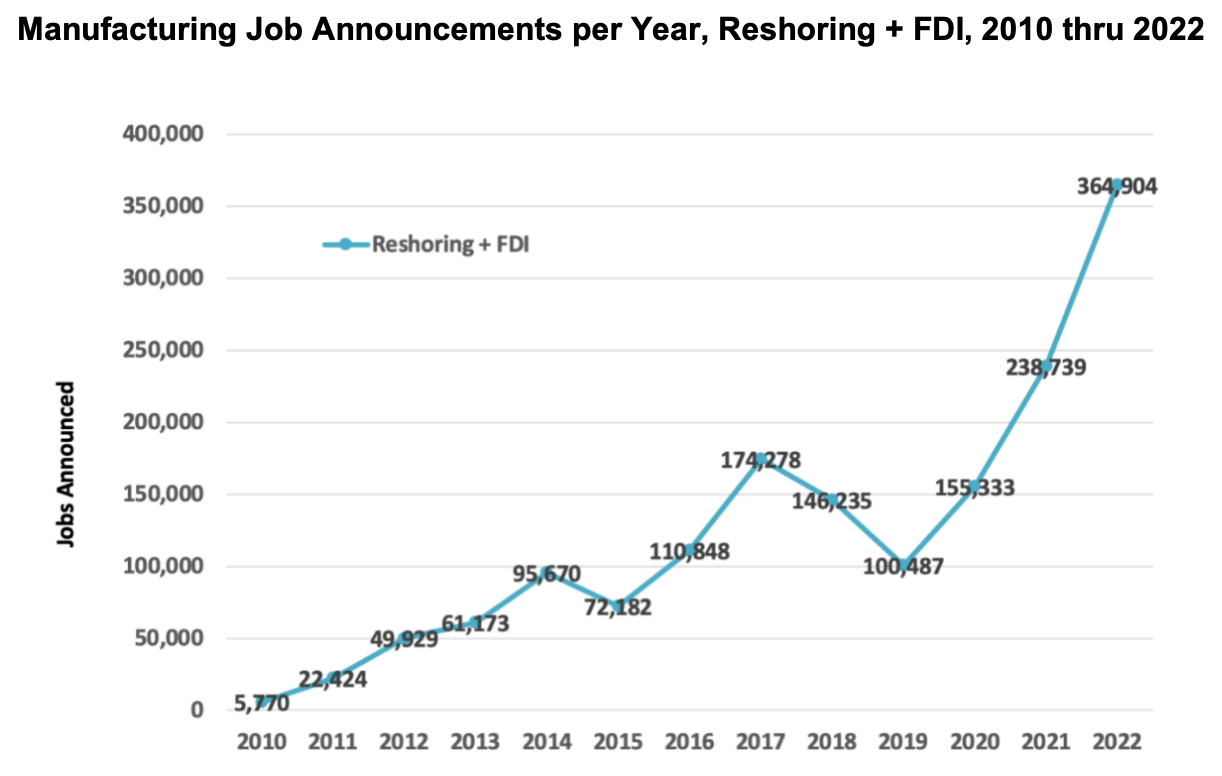

In the three years since the pandemic's onset, a growing number of U.S. businesses have made significant investment in domestic production, a departure from a longtime historical trend of overseas operations. One byproduct of this is the 53% year-over-year increase in manufacturing jobs on U.S. soil.

Reasons for Onshoring Manufacturing

While overseas production can have certain benefits, the outlook for domestic production has seen far greater optimism for a variety of reasons:

Geopolitical Risks

Geopolitical tensions and events have exposed the degree (and vulnerability) of interconnectivity in the global marketplace. The conflict in Ukraine has significantly affected energy costs and grain shipments, leading to supply chain disruptions due to sanctions on Russian imports and Ukraine redirecting its domestic factories to wartime defense production. Heightened tensions with China have prompted the U.S. government to prolong trade tariffs and allocate billions for boosting domestic manufacturing, particularly in microchip technology, as the U.S. seeks less dependence on its manufacturing counterpart.

Cost

Shipping entails significant additional costs, requirements, and sometimes backlogs that have put significant strain on inventory levels, especially for assembled final products awaiting a fraction of their subcomponents from overseas. Inventory carrying costs and, perhaps more importantly, opportunity cost on delayed assembly directly affect the bottom line of all sized manufacturers. Lastly, freight costs have seen a substantial increase due to increasing fuel costs, labor shortages, and pandemic shutdowns. U.S. manufacturers only have so much margin to work with until an alternative must be found. Fortunately, gas, electricity, and chemical prices in the U.S. are measurably lower than those abroad and make up for higher domestic labor costs.

Supply Chain Volatility and Control

The global supply chain has not proven to be as predictable as it once was. Compared to 2021, understocked inventory as a primary concern increased by 300% among manufacturing executives in 2022. OEMs (Original Equipment Manufacturers) demand high quality products fast and can penalize their vendors for even infrequent, small inventory shortcomings. Even in the case of slightly-higher cost, locally produced parts, OEMs like John Deere, GM, and even Apple have increasing preference for the expedience, control, and certainty of U.S.-based vendor production to fulfill ever-changing market demands.

What does this mean for my company?

As US manufacturing continues to gain momentum under these patterns, certain investment priorities are becoming increasingly crucial for mid-sized companies to succeed.

- Workforce Investment and Retention Rates

- Steady quality labor has been one of the biggest issues of the past decade for manufacturers. But attaining quality employees is not nearly as important as retaining quality workers. Monitoring employee performance data via your ERP system and running a comprehensive incentive program can be the difference makers when ensuring your workforce is top-notch.

- Unified, Comprehensive ERP Systems

- Your departments need immediate, complete access to the data necessary to fulfill their responsibilities. For many manufacturers, their inadequate ERP system is their operational (and profitability) bottleneck. If your ERP system does not have a track record of giving your operations and management the information it needs to make proper decisions, then throwing more money at it probably is not the solution. Read more about SV ERP by clicking here.

- Automation

- Manufacturers seeking efficient operational output and cost savings can benefit immensely from streamlining processes via automation. Companies that push the limits regarding what can be automated enable their business to win and strengthen their business on multiple other fronts. In an era where workers seem impossible to come by, the business potential of automating simple processes or operations is endless, and can be the difference between exceeding or falling short of profitability and growth objectives.

Conclusion

As the start of 2024 nears and onshored manufacturing continues to accelerate industrial production in the United States, reliance on overseas sources for raw materials and manufacturing capacity is decreasing, fortunately. Meanwhile, top manufacturers are anticipating where they need to devote more investment in order to seize the opportunity presented before them. Ultimately, the U.S. manufacturing outlook is optimistic for the upcoming years; with that optimism comes a sense of urgency to build long term business value, before the window of opportunity closes.